Hydraulic Pumps: Basic Engineering Principles of Hydraulic Pumps

The hydraulic pump is a device that transforms mechanical energy (torque and motor speed) into hydraulic (flow).When a pump operates, it fulfills two functions: first, its mechanical action creates a vacuum in the suction which allows the atmospheric pressure to force liquid from the tank or reservoir towards the entrance of the same. Second, the same action delivers this liquid to the pump outlet and pushes it towards the hydraulic circuit.

It is important to note that a pump produces movement of the liquid (flow), the pumps do not generate pressure. The necessary flow is generated for the development of the pressure in the system, which is really the result of resistance to flow. For example: the pressure of a fluid at the pump outlet is zero if it is not connected to a system or load. Similarly, if a pump is delivering flow to a system, the pressure will only reach the level necessary to overcome the resistance of the load applied to it.

Classification of the Pumps

All pumps can be classified as: positive displacement and negative displacement or roto-dynamic. The latter produce a continuous flow, however, as they do not have an internal positive sealing system that prevents slippage, their output flow varies considerably with changes in the pressure in the system. Centrifugal and propeller pumps are examples of negative displacement pumps.If the output of a negative displacement pump was blocked, the pressure would increase, but the flow rate would drop to zero. Although the pumping element would continue to move, the flow rate would be canceled due to internal slippage or leakage.

On the other hand, in a positive displacement pump, the internal leakage is negligible compared to the output flow. If the outlet port is blocked, the pressure would increase instantaneously to the point that the pumping element, the housing or other internal element fails (it would probably explode, unless the axis fails first), or the main drive would shut down due to overload.

Principle of Positive Displacement

A positive displacement pump is one that displaces (delivers) the same amount of fluid for each rotation cycle of the pumping element. Constant delivery during each cycle is possible thanks to the tolerances that exist between the pumping element and its container (stator, piston block, housing, etc.). The amount of liquid (internal leakage) that passes through the pumping element in a positive displacement pump is minimal and negligible compared to the theoretical maximum pump flow rate and the volume per cycle remains relatively constant despite changes in system pressure It should be noted that if the internal leak is substantial, it is an indication that the pump is not operating properly and may need to be repaired or replaced.Positive displacement pumps can be fixed or variable. The flow rate of a fixed displacement pump is kept constant throughout the pumping cycle and at a specific speed, while that in a variable displacement pump can be modified by altering the geometry of the displacement cavity.

Other names used to describe these types of pumps are hydrostatic for those with positive displacement and hydrodynamic for those with negative displacement. Hydrostatic means that the pump converts mechanical energy to hydraulic with a relatively smaller amount of fluid and speed. In a hydrodynamic pump, liquid velocity and movement are greater; The outlet pressure is dependent on the speed at which the liquid operates.

Reciprocating Pumps

Figure 1: Reciprocating pumpThe positive displacement principle is clearly illustrated in the reciprocating pump, the most elementary of this type shown in Figure 1. As the piston extends, the partial vacuum created in the pumping chamber draws liquid from the reservoir through of the non-return valve at the inlet to it. This partial vacuum helps the outlet check valve to settle firmly. The volume of liquid sucked into the chamber is known due to the geometry of the housing, in this case, a cylinder. As the piston retracts, the inlet check returns again, closing the valve, and the force of the piston raises the outlet check, forcing the liquid out of the pump into the system. The same amount of liquid is forced out of the pump in each reciprocating cycle.

All positive displacement pumps deliver the same amount of liquid for each cycle (regardless of whether they are reciprocating or rotating). It is a physical characteristic of the pump and does not depend on the drive speed. However, the higher it is, the greater the total volume of liquid it will deliver.

Rotary Pumps

In a rotary pump, the rotation takes the liquid from the suction to the outlet. Rotary pumps are generally classified according to the type of element that transmits to the liquid, so we speak of a gear pump, rotating piston, vanes or rotary piston pumps.Figure 2: External gear pump

The external gear pumps can be divided into external and internal. A typical external gear pump can be seen in Figure 2. These pumps can be straight, helical, or bihelicoidal gears. Straight gears are the easiest to machine and are the most commonly used. Helical and bihelicoidal are quieter during operation, but they are more expensive.

The gear pump produces flow leading to the fluid between the teeth of two coupled gears. A gear is driven by the shaft and in turn drives the intermediate gear or idler . The chambers that form between adjacent teeth are covered by the housing and side plates (also called wear or pressure plates).

A partial vacuum is created at the pump inlet as the teeth disengage. The liquid enters to fill the space and is transported by the external part of the gears. As the teeth engage again at the pump outlet, the fluid is forced out. The volumetric efficiency in this type of pumps can reach levels of 93% in optimal conditions. The play between the faces of the gears, teeth, ridges, and the housing generate almost constant losses over any volume pumped at constant pressure. This means that volumetric efficiency at low speeds and flows is poor, so gear pumps must be used close to their maximum design speeds.

Although the loss through the openings increases with pressure, it is almost constant with changes in speed and flow. For a pump, the loss increases by approximately 1.5 gpm from 0-2,000 psi regardless of speed. The change in sliding or internal leakage with pressure has little negative effect on performance when operating at high speeds and flow rates. External gear pumps are comparatively immune to oil contamination, which will increase the rate of wear and decrease efficiency, but sudden failures are rare.

Figure 3: Rotary piston pump

The rotary or lobular piston pump is a rotary external gear pump, as you can see in Figure 3. It differs from the conventional gear pump in the way they are driven. As we saw earlier, in the external gear pump one drives the other, while in the lobular, both are driven through gears located outside the pumping chamber.

The screw pump is axial flow, with an operation similar to that of a rotary compressor. The three types are: one screw, two and three. In a single screw, a spiral rotor moves eccentrically in an internal stator. The two-bolt consists of two interconnected parallel rotors that rotate in a machined housing with demanding tolerances. On the other hand, the three-bolt consists of a centrally operated rotor with two intermediate rotors attached, and they rotate in a machined housing with demanding tolerances.

The flow through a screw pump is axial and in the direction of the power rotor. The hydraulic fluid at the inlet that surrounds the rotors is enclosed as they move. This fluid is then pushed evenly with the movement of the rotors through the shaft and forced outwards on the other side.

The fluid delivered by a screw pump does not rotate, moves linearly. The rotors work as endless pistons that continuously move forward. There are no pulsations or at high speeds. The absence of these and the fact that there is no metal-metal contact results in a very silent operation.

The larger pumps are used as low pressure, pre-filling large volumes in presses. Other applications include hydraulic systems in submarines and other uses where noise must be controlled.

Figure 4: Internal gear pump

Figure 4 shows an internal and external gear. Because these pumps have one or two less teeth on the inner wheel than on the outer wheel, the relative speeds between them are low. For example, if the number of teeth on the inner and outer wheel were 10 and 11 respectively, then one would rotate 11 times while the other does 10. This low relative speed implies a low wear rate. These pumps are small and compact.

The internal gear pump with half-moon seal consists of an internal and an external gear separated by a half-moon-shaped seal. The two wheels rotate in the same direction, making the internal faster than the external. Hydraulic oil is introduced to the pump at the point where the teeth begin to separate and is taken to the outlet in the space between the crescent and the teeth of both wheels. The point of contact of the teeth forms a seal, as does the distance with the tip of the crescent. Although this pump was generally used for low flow rates in the past, at pressures below 1,000 psi, a 2-phase model at 4,000 psi was introduced to the market a few years ago.

The 'geotor' type internal gear pump consists of a pair of cogwheels that are always sliding together. The internal one has a tooth more than the gerotor and both wheels move in the same direction. The oil is introduced into the chamber where the teeth are separating, and comes out when they are reattached. The seal is provided by the sliding contact. Generally, the internal gear pump of this type has a better volumetric efficiency than the half-moon seal at low speeds. The volumetric and total efficiency of these pumps is in the same range as external gear pumps. However, its sensitivity to contamination is superior.

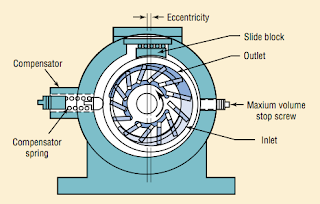

Figure 5: Vane pump

In vane pumps,a number of them slide into cavities in a rotor that travels in a housing or ring. The configuration of the housing may be eccentric with respect to the rotor shaft, or oval, as shown in Figure 5. In some designs, centrifugal force keeps the blades in contact with the housing, while they are forced into inside and outside the cavities due to the eccentricity of the housing. In a vane pump, low-tension springs keep the vanes pressed against the housing; In another design, pressurized pins are responsible for fulfilling this function. During the rotation, as the space or chamber enclosed by the vanes, rotor and housing increases, a vacuum is created and the atmospheric pressure forces oil into this space, which represents the pump inlet.

Figure 6: Balanced vane pump

Balanced and unbalanced vane pumps - the pump illustrated in Figure 5 is unbalanced, because all the pumping action occurs in the chambers on one side of the rotor and the shaft. This design generates a lateral load on both sides. Unbalanced vane pumps can be fixed or variable displacement. Some pumps have a balanced construction in which an ellipse-shaped envelope forms two pumping areas on opposite sides of the rotor, so that the side loads cancel each other out, see Figure 6. Balanced vane pumps only come in designs Fixed displacement

In an unbalanced variable pump, Figure 7, the displacement can be varied through the use of an external control such as an adjustment wheel or pressure compensator. The control moves the cam ring so as to change the eccentricity between the ring and the rotor, thus varying the size of the pumping chamber and hence the displacement per revolution.

Figure 7: Variable vane pump with pressure regulator

When the pressure is high enough to overcome the spring force of the pressure regulator, the ring moves to decrease eccentricity. The spring adjustment determines the pressure at which this happens. As centrifugal force is required to hold the vanes against the housing and the seal between the parts, these pumps are not ideal for low speed service. Operation below 600 rpm is not recommended. If springs or some other mechanism is used to hold the vanes against the ring, efficient operation at speeds of 100 or 200 rpm is possible.

Vane pumps maintain their efficiency for a long time because the compensation for wear between the housing and the ends of the vanes is automatic. As the vanes wear, they will move further out of their cavities to maintain contact with the housing. These pumps, like many others, are available in double configuration (two units in the same housing) and can be the same or different size. Although they are mounted and actuated as simple pumps, they are hydraulically independent. Another variation is the unit in series: two pumps of the same capacity connected in series, so that the output of one feeds the other. This arrangement allows to obtain twice the pressure normally available for this type of pump.

Piston pumps

Figure 8: The axial piston pump varies its displacement by changing the angle of the swingarmThe piston pump is a rotating unit that uses the principle of the reciprocating pump to generate flow. Instead of using a single piston, these pumps have multiple piston configurations in a cylinder. Part of the mechanism rotates around an axis to generate reciprocating movements, which extract fluid to each cylinder and then deliver it, producing the flow. There are two main types, axial and radial; both are available fixed or variable displacement. The second usually has a reversible variable displacement capacity (over center).

Variable displacement pumps tend to be larger and heavier than fixed ones. This is because additional controls are required, such as: mechanics, electric motors, hydraulic cylinders, servos, among others.

Axial piston pumps - the pistons in an axial piston pump reciprocate in parallel to the centerline of the cylinder or kite shaft. In this way the rotational movement becomes an axial reciprocating movement. Most of these pumps have multiple pistons and use non-return valves or covers with gantries to direct the flow from the inlet to the outlet.

In-line piston pumps - the simplest type of axial piston pump is the swingarm design, in which a barrel is driven by the shaft. Pistons introduced into the barrel cavities are connected through their heads and a retaining ring, so that they are supported by an angled swingarm. As the barrel rotates, Figure 8, the piston heads follow the swingarm, causing the pistons to perform a reciprocating action. The porches are connected internally to the control plate, so that they leave when they pass through the entrance, and enter when they pass through the exit. In these pumps the displacement is given by the size and number of pistons, as well as the length of the stroke, which varies with the angle of travel.

There are several designs of variable pumps, but in all there is generally some type of connection between the swingarm and a servo system, which when connected with the different regulators, allow the desired control: compensation of pressure, flow, power, etc.

Inclined shaft pumps - this pump consists of a shaft that transmits the rotation to the pistons, a cylinder or kite and a control surface in front of the holes of the kite that communicates with the input and output frames. In this type of pumps the shaft and the barrel are forming an angle to each other.

As the plane of rotation of the pistons is at an angle to the plane of the control plate, the distance between any of the pistons and the same changes continuously as they rotate. Each piston separates half of a revolution from the control plate, while the other half approaches.

The control plate is configured so that its input frames are connected to the part of the rotation where the pistons are separated from it (aspiration), while its output passage is connected to the middle where the pistons approach it forcing the liquid out of the pump. Inclined shaft pumps come in fixed and variable displacement configurations, but are not reversible.

Also read: Piston Pump Hydraulic: What it is, types, parts and how a hydraulic piston pump works?

Figure 9: Radial piston pump

In radial piston pumps,the pistons are located radially in relation to the axis in a cylinder, so they move perpendicularly to it during rotation. There are two basic types: one uses cylindrical pistons, and the other ball-shaped. They can also be classified by the arrangement of the porches: check valve or pin. They are available in fixed and variable displacement, and variable over center (reversible). In stationary pin pumps as shown in Figure 9, the barrel rotates on a pin and inside a ring or rotor. As it rotates, centrifugal force, preload pressure, or some other form of mechanical action causes the pistons to follow the inner surface of the ring, which is eccentric with respect to the axis of the kite. As the pistons reciprocate,

The size and number of pistons and the length of the stroke determine the displacement of the pump. This can be varied by moving the reaction ring to increase or reduce the stroke of the pistons, thus varying the eccentricity. Different types of regulators are available to fulfill this purpose.

Figure 10: Flow pressure curve of a fixed displacement pump

The piston pumps have certain similarities with the rotary piston in the fact that the pumping is the result of the reciprocating action of pistons in a cylinder. However, in these the cylinders are fixed; They do not rotate around the axis. The pistons can be reciprocated by a camshaft, eccentric on an axis, or by an oscillating plate. When eccentrics are used, the return stroke is made through springs. As valves or plates that cover and uncover porches cannot be used as rotation occurs, inlet and outlet check valves can be used in these pumps.

Due to their construction, these pumps offer two qualities that others do not have: on the one hand, the positive seal between inlet and outlet, allowing higher pressures without excessive internal leakage. On the other hand, in many pumps of this type, the lubrication of moving parts except the pistons and cylinder can be independent of the liquid being pumped, which allows liquids with poor lubrication properties to be used. The volumetric and total efficiencies are close to those of axial and radial piston pumps.

Measurement of pump performance

Figure 11: Flow pressure curve of a variable displacement pump with ideal pressure and flow compensation

The volume of fluid pumped per revolution is calculated by the geometry of the cavities that carry it. A pump never delivers this theoretical or calculated flow. How close this number is to reach is called volumetric efficiency. It is calculated by comparing the theoretical flow with the practical or current one and varies with the speed, pressure and construction of the pump.

The mechanical efficiency is also less than perfect, because there are frictional energy losses at the entrance. The total efficiency of a hydraulic pump is obtained by multiplying its volumetric and mechanical efficiencies.

Pumps are generally classified by their maximum operating pressure capacity and flow, in gallons per minute (gpm), or liters per minute (lpm); at a specific drive speed in rpm.

Selection comparing the power of the pump with the load

Figure 12: Circuit of a typical pressure regulatorPressure compensation and load sensing are terms commonly used to describe qualities of a pump that improve the efficiency of its operation. Sometimes they are used with the same meaning, which represents an error that is clarified once you understand the differences in how each of these options works.

To start this process, consider a simple circuit using a fixed displacement pump, rotating at a constant speed. The circuit is efficient only when the load needs are maximum, since the pump delivers flow at maximum pressure regardless of the load demand. The pressure relief valve prevents excessive pressure increase, sending high pressure fluid to the tank when the system reaches the set pressure. As Figure 10 shows, there is a loss of energy when the load requires less than the maximum flow or maximum pressure. This unused energy is converted into heat that must be dissipated. The total efficiency of the system could reach the order of 25% or less.

Variable pumps, equipped with displacement controls like the one shown in Figure 11, can save most of this wasted power when a load is moved. Variations in controls include: handwheel, lever, cylinder, servo, and electrohydraulic servo controls. Although they allow to regulate the exact flow required by a specific load, these controls do not have the possibility of limiting the pressure or power. Therefore, other provisions must be installed to fulfill this purpose, in addition that the main drive must have the maximum power. Additionally, when a pump supplies a circuit with multiple loads, the uniformity of load and flow rates is compromised.

One way to design a system in which a pump controls several loads is by using a proportional pressure controller, as shown in Figure 12. A servo spring keeps the pump at maximum displacement. When the load exceeds the adjustment of the regulator, the pressure acts against the slide, thus coping with the force exerted by the spring on the other side. The slide then travels to the spring chamber, communicates fluid from the pump outlet to the servo or control piston and reduces its displacement. The slide will return to its central position once the pump pressure matches the regulator set pressure. If a load blocks the actuators, the pump flow becomes zero.

Figure 13: Flow pressure curve of a variable displacement pump with pressure regulator

By using a variable displacement pump with pressure regulator instead of a fixed displacement pump, the power requirements of the system are reduced considerably, as shown in Figure 13. The output flow of this type of pump varies according to a predetermined pressure, detected by a hole in the regulator. Because the regulator itself operates with pressurized fluid, the discharge pressure must be adjusted to a higher level - say 200 psi above the maximum load pressure. So if the loading pressure of a pump with a pressure regulator is 1,100 psi, it will vary its displacement (and therefore its flow) based on a discharge pressure of 1,300 psi.

A two-stage pressure regulator , like the one shown in Figure 14, uses pilot pressure through a hole in the first stage to create a pressure drop of 300 psi. This pressure drop generates a force on the slide against which the main spring is opposed. Pilot flow flows to the tank through a small pressure relief valve. A spring chamber pressure of 4,700 psi allows an adjustment of 5,000 psi for the regulator. An increase in pressure above the level of adjustment moves the main slide to the right, connecting the output flow with the pump servo, which exceeds the spring force, thus reducing the displacement of the pump so that it balances With the load requirements.

Figure 14: Hydraulic circuit of a pump with two-stage pressure regulator

The misconception indicated above arises from the observation that the output pressure of a pump with a pressure regulator may fall below the setting while the actuator is moving. This does not happen because the pump is detecting the load, but because it is under-sized for the application. The pressure drops because the pump cannot generate enough flow to maintain the load. When properly sized, a pump with pressure regulator will force enough fluid through the compensator orifice to operate.

Dynamically Superior

With respect to its function, a two-phase pressure regulator is identical to the proportional one shown in Figure 12. The dynamic performance of the two-phase is however superior. This is obvious when analyzing a transition that involves an unexpected reduction in flow demand, starting at the stage of maximum displacement at low pressure.Figure 15: Typical performance of simple and two-stage compensators

The single stage regulator will send fluid to the servo only when the discharge pressure of the pump reaches its setting pressure. The main slide of the two-phase regulator begins to move as soon as the discharge pressure minus the spring chamber pressure exceeds the setting of 300 psi. As pilot flow flows through the hole and due to the flow required to compress the fluid in the spring chamber, this pressure is below the discharge pressure of the pump. This causes the slide to unbalance and move to the right.

The reduction in displacement starts before the discharge pressure reaches the regulator set pressure, see Figure 15. Note that in a system equipped with an accumulator, a two-stage regulator helps in the least. In hydraulic excavator systems, however, the superiority of such a control is evident: it provides the system components with greater protection against changes in transient pressure.

Load sensing control or load sensing

Figure 16: Hydraulic circuit of a proportional regulator with load detectionA similar regulator that has great popularity, is the load sensing or load sensing , sometimes called a power matching, shown in Figure 16. The single phase valve is almost identical to that of the single phase pressure regulator shown in Figure 12, with the exception that the spring chamber is connected downstream of a variable hole, rather than directly to the tank. The load sensing regulator slider reaches equilibrium when the pressure drop through the variable orifice equals the pressure of 300 psi of the spring adjustment.

Any of the three load sensing signals control a pump with this regulator: no load, during work, and discharging pressure. In the no-load mode, the lack of loading pressure causes the pump to produce zero flow at the spring or unloaded pressure. When in working position, the load pressure causes the pump to generate flow in relation to a predetermined pressure drop. When the system reaches the maximum pressure, the pump maintains this pressure by adjusting the output flow.

As with the pump with pressure regulator, it has a section with pressure regulation, but it is modified to receive two signals, not just one. As with the previous one, it receives a signal that represents discharge pressure, but also receives a second one that represents the load pressure. This signal originates from a second hole located downstream of the first. This orifice can be a flow control valve located immediately after the pump is released, the opening of a directional valve, or simply a restriction in a pipe.

Figure 17: Flow pressure curve of a pump with load sensing control or load sense

The comparison of the two pressure signals in the regulator allows the pump to detect both load and flow, which reduces energy consumption even more as can be seen in Figure 17. The pump output varies according to the pressure differential of the two holes. Just as the pump with pressure regulator increases its discharge sufficiently to drive the regulator, the discharge pressure of a pump with this regulator is generally between 200-250 psi above the loading pressure. Additionally, a pump with this regulator can follow the load and flow requirements of a single or multiple functions, relating the power to the maximum pressure required. This allows the minimization of energy consumption and generates the least possible heat.

Operator control

If the variable orifice is a manually operated flow control valve, the system can operate in an operator-directed load sensing mode. As the valve opens, the flow increases proportionally (a fixed pressure drop through a hole that constantly increases its diameter), at a pressure slightly above the load pressure.Figure 18: Hydraulic circuit of a load sensing regulator and pressure limitation

As suggested in Figure 17, the waste energy is very low when a charge sensing regulator is used in a variable pump. Since the control detects the pressure drop and not the absolute pressure, the use of a pressure relief valve in the system is required. And although we can say that the problem is solved with the use of a load sensing and pressure regulation type compensator, it should be noted that the system must be protected with an external pressure valve so that the pressure peaks resulting from the switching of directional valves, be properly released.

Aso read: